Regenerate catalysts from petroleum refining

Catalysts

Refining

Catalysts play a crucially important role in the petroleum refining industry since they are used to convert and purify crude oil.

These catalysts are small elements that resemble granules (various shapes) and are called “hydrotreating catalysts”. Metal oxides are deposited on an alumina or silica substrate and these catalysts are used to create chemical reactions which turn crude oil into petrol or diesel.

However, catalysts gradually lose their properties and are then no longer able to retain all the unwanted elements contained in crude oil, so need to be replaced by new ones.

The oil refining industry

The oil refining industry thus generates a great deal of used catalysts which become highly toxic waste if not recycled.

One solution is to regenerate these catalysts by cleaning them up and returning them to their original state.

Our mixers

No solution seems to match your field of activity or your appliances ?

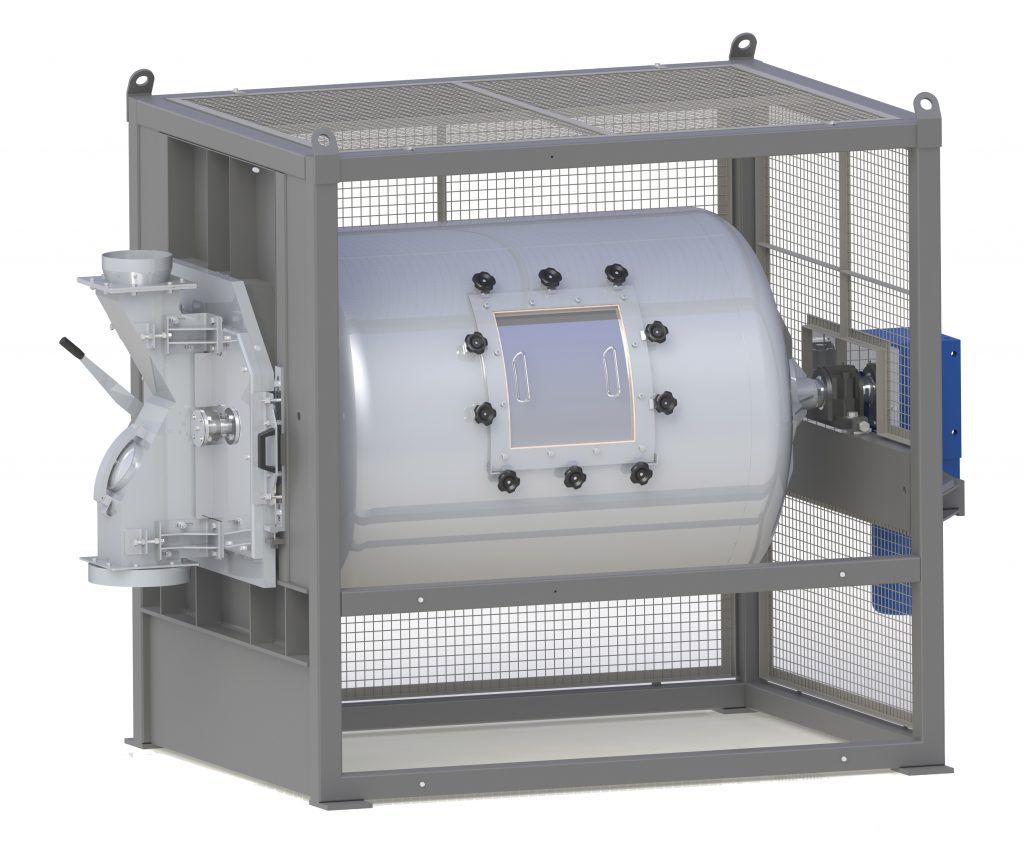

Our rotating drum mixers

Our rotating drum mixers are perfectly suited to these operations since the gentle mixing action ensures the shape of these catalysts is not altered. Moreover, our rotating drum mixers can be equipped with liquid spraying systems to ensure a homogeneous chemical reaction during the mixing process.