Make your mixes for the food industry in compliance with regulatory requirements

Drawing from its in-depth awareness of the food industry regulations, SOFRADEN has developed a range of equipment for mixing powdery (flour, sugars…), granulated or pasty products.

Food mixers, dispersers

The food industry produces a wide variety of products in liquid, pasty or solid form (powders, granules…).

Each application has its own very strict requirements which call for precise mixing specifications. Homogeneity of the mix and preservation of the physicochemical properties of fragile and delicate ingredients are extremely important aspects in the context of food destined to human consumption.

Some examples of food products mixing:

Raw materials

Raw materials :

Raw materials: mixing of various types of flour, cereals, sugars or making a pre-mix...

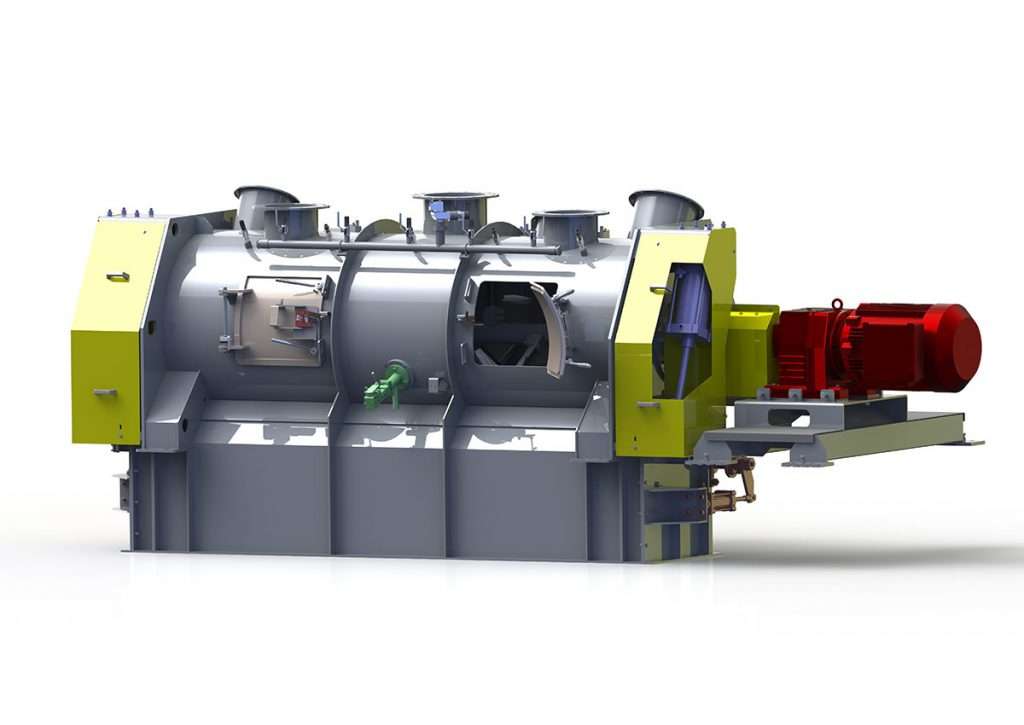

Our MIB intensive blade mixers and our MHR ribbon mixers are perfectly suited for these applications.

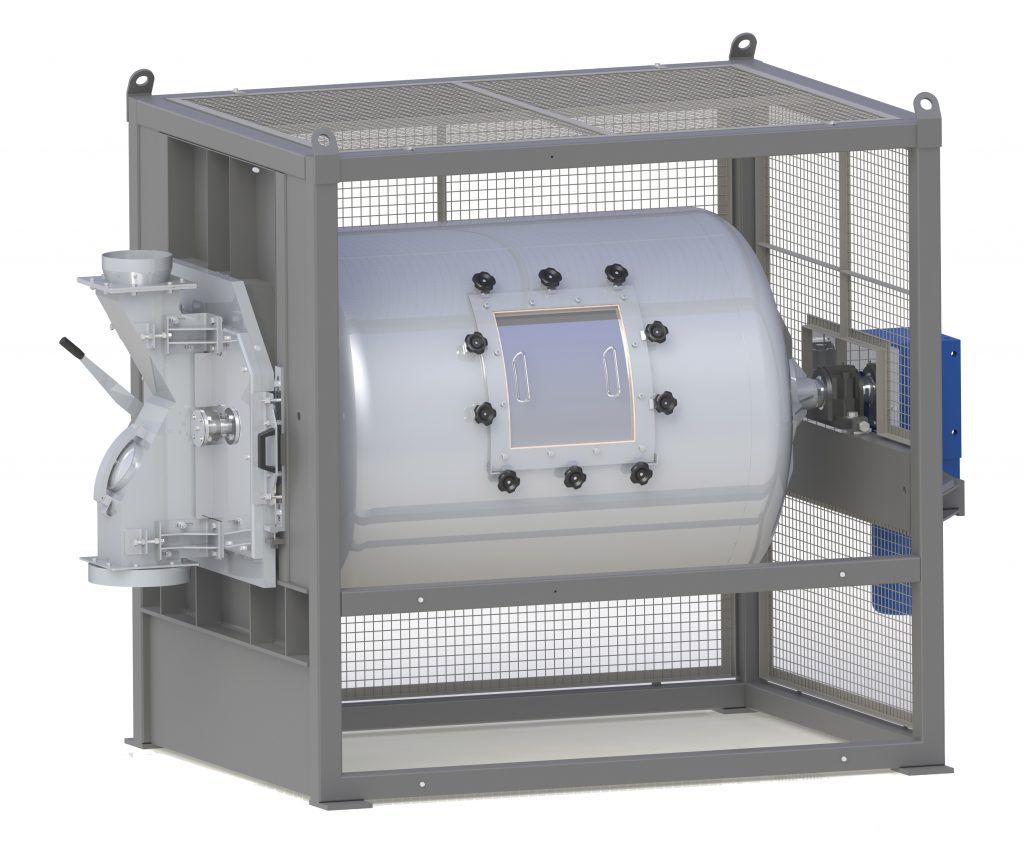

Our Sofragir rotary drum mixers can also be used for homogenization operations such as mixing aromatic herbs for example.

In terms of food mixer, discover our "animal feed mixer"

FFlavouring and colouring processes can be carried out by injecting liquid flavours or colourings into powders or crystals.

Our rotating drum mixers may be equipped with liquid spraying systems. The gentle mixing action does not have a detrimental effect on the crystals and guarantees highly homogeneous flavoring or coloring.

This process is frequently resorted to in the sugar and tea industries but also in enology (treatment of oak chips for instance).

Our SOFRAMIX reactors/dispersers are used to make emulsions, mayonnaise being the most obvious example. They can also be used to mix or disperse different raw materials, in order to obtain soups, milk drinks, vegetable puree, fruit compote…

For mixing formulations based on dry materials, our industrial mixers for mixing solids will meet your needs: MIB intensive paddle mixers, MHR ribbon mixers, SOFRAGIR rotating tank mixers.

No solution seems to match your field of activity or your appliances ?