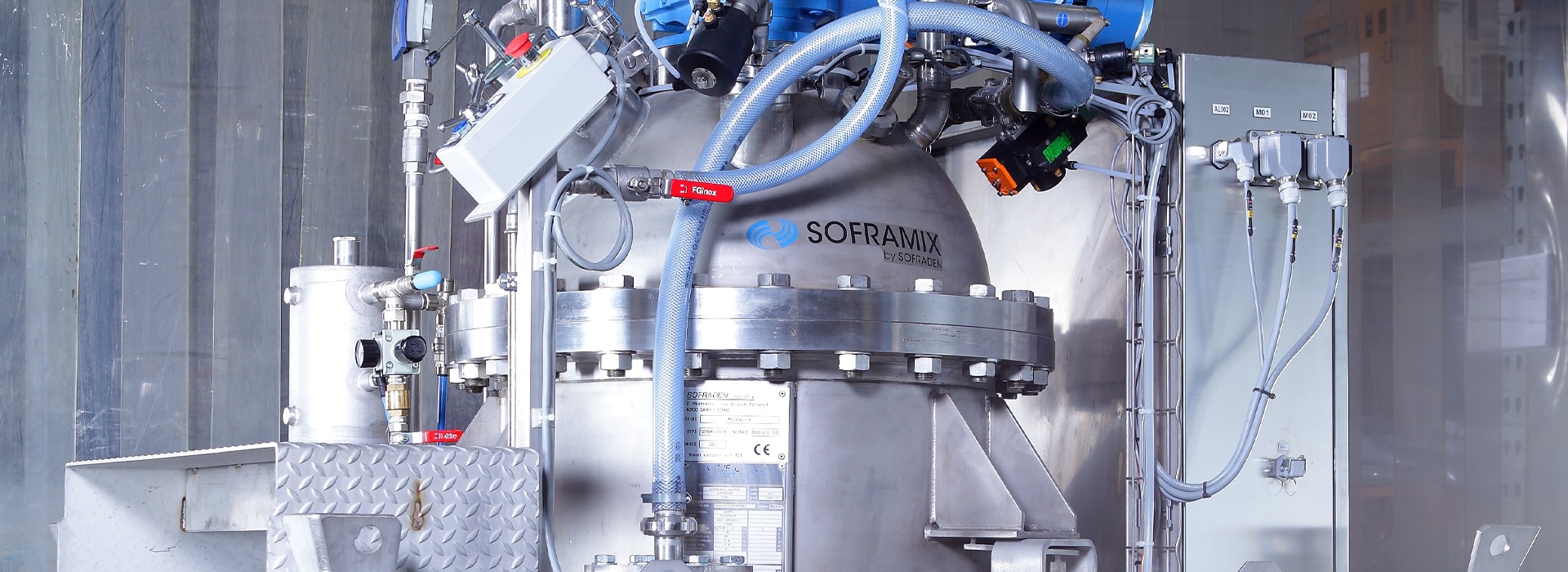

SOFRAMIX, a flexible and scalable solution

Reactor-disperser

SOFRADEN has developed a range of reactors / dissolvers / dispersers called SOFRAMIX.

We developed this range of disperser mixers with our clients’ efficacy and productivity requirements in mind. Our goal was to design a flexible and scalable solution to meet the needs of all your applications, ranging from the most basic to the most complex.

Particular attention was paid to cleanability of the machine: our fully automated Clean In Place (CIP) system cleans vessels thoroughly without human intervention. This guarantees reproducibility, enhanced productivity and a hazard-free cleaning operation.

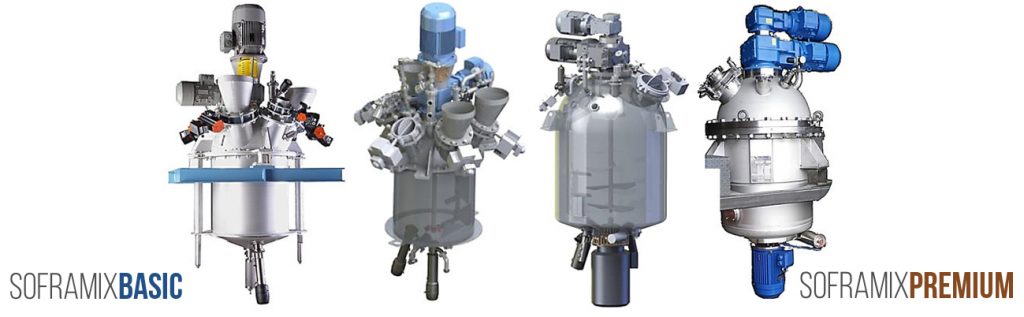

To meet your specific performance and cost requirements, this category comes in two versions: SOFRAMIX BASIC and SOFRAMIX PREMIUM.

To meet your specific performance and cost requirements, this category comes in two versions: SOFRAMIX BASIC and SOFRAMIX PREMIUM.

- SOFRAMIX BASIC

- SOFRAMIX PREMIUM

Both these versions of disperser mixers share the same main features, i.e.

- Vertical vessel with conical bottom to optimize dispersion of materials and discharge

- Liquids and powders fed through the vessel dome (gravity feed) or the bottom of the vessel (vacuum assisted feed)

- Dispersion tools are adapted and sized depending on the level of viscosity and finished product specifications (emulsion mixer, dispersion mixer...)

- Double outer shell to heat or cool the product

- Clean In Place system (CIP)

- Vessel kept under vacuum or at a constant pressure

The SOFRAMIX Premium version provides optimum performance and enhanced flexibility. Compared to the SOFRAMIX Basic version, the dispersion tool located in the bottom of the vessel has many advantages:

- Mixing of products with higher dynamic velocity

- Broader range of dispersion tools which are easily interchangeable

- Enhanced performance thanks to presence of a central propeller

Our viscous product mixers can be manufactured using a wide range of materials and designed in accordance with your ATEX classification.

Main assets of our reactors/dispersers

- Quality and speed of dispersion

- Quick discharge that minimizes product retention

- Fully automated Clean In Place system – reproducibility of the finished product

- Deaeration / debubbling of the finished product

Variety of options

We can also supply auxiliary Clean In Place- CIP, vacuum group, temperature controller...

TEST AND VALIDATE YOUR APPLICATIONS

IN OUR TEST CENTER

SOFRADEN is equipped with a test centre, equipped with different types of mixers from our range. These mixers are at your disposal to validate your applications.

Boost your productivity

with our services

Training, audit, renovation … how to get the most out of your facilities

None of thoses solutions fully match your applications ?

As well as these standard reactor-disperser, we can also design and manufacture ‘tailor-made’ solutions to meet your specific needs.